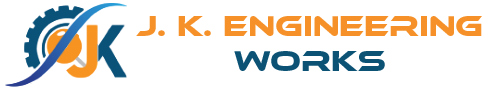

Coating Pan Manufacturers in Pune, suppliers, and exporters in Pune

J.K. Engineering Works is one of the leading coating pan manufacturers in Pune, suppliers, and exporters in Pune. Our offered coating pans are produced utilizing top-notch machines and methods. We use top-quality raw materials and advanced machinery to create a range in line with international standards. A coating pan GMP model is mostly used in the confectionery industry.

A coating pan machine is used in the food and pharmaceutical sectors for coating several items, including candies, lollipops, tablets, and capsules. The coating substance is either melted or dissolved in a liquid, and the item is spun in the pan to guarantee a uniform coating. It involves coating layers of chocolate, sugar syrup, or other compounds using a coating pan. The coated item may include almonds, peanuts, hazelnuts, raisins, malted milk balls, cherries, candied ginger, or nougat.

Technical Specifications of Coating Pan:

Being a coating pan manufacturers in Pune, we supply this pan with lots of specifications, as below:

| Specification | Details |

|---|---|

| Machine Type | Stainless Steel Coating Pan |

| Material Used | Stainless Steel |

| Brand | JK Engineering Works |

| Output Power | 1.5 KW |

| Phase | Three Phase |

| Input Voltage | 440V |

| Capacity | Up to 70 kg |

| Gross Weight | 250 Kg |

| Automation Grade | Automatic or Manual |

| Frequency | 50 HZ |

| Features | Easy to maintain and clean |

Types of Coating Pan:

We have become one of the leading coating pan manufacturers in Pune for producing and supplying different kinds of coating pans worldwide. Below are mentioned a few types:

- Perforated Coating Pan: The Perforated Coating system uses completely or partially perforated drums that spin within a sealed housing along their horizontal axis. This system offers more effective drying of coating material compared to traditional methods, saving time. It is commonly used in candy production across various industries.

- Bottom Spray Coating Pan: This pan uses airflow to elevate and move tablets or pellets within a coating chamber. The automatic spraying system ensures uniform texture, applying the coating solution from the bottom for complete and uniform coverage on every surface. It is widely used for controlled-release drug formulations.

- Revolving Coating Pan: This pan applies a consistent and smooth layer of coating material, like sugar or chocolate, with regulated spinning. Adjustable airflow, temperature, and rotational speed allow for a controlled coating thickness and finish, preserving the shape and texture of the item.

- Side Vented Coating Pan: The coating solution is applied through a spray from the side of the pan, with airflow channeled through vented openings. Its side-vented configuration ensures a more regulated and tidier coating environment, reducing coating time and enhancing efficiency.

Advantages of a Coating Pan:

As a coating pan suppliers in Pune, we produce top-grade pans with numerous advantages, including:

- Consistency in Coating: Our coating pans offer a consistent application of coating materials. It guarantees that every product is evenly coated, which is required for both appearance and taste.

- Large-Scale Production: They are capable of processing large quantities of products at a time. Thus, it helps to improve production efficiency and lower labels or expenses relative to manual coating techniques.

- Increased Appearance: The coating procedure can improve the taste and consistency of the item, which helps increase its attractiveness to buyers.

- Adjustable Parameters: A semi-automatic SS sugar coating pan is equipped with adjustable speed and temperature settings. These parameters enable operators to tailor the coating process to meet the particular needs of the item being coated.

Applications of Coating Pan:

As a leading coating pan exporters in Pune, A coating pan is equipped with a big circular pan that can rotate and proceed with the coatings of the substances. Our coating pans are widely used in candy, food, or pharmaceutical manufacturing units for coating substances such as:

- Nut, Dryfruits

- Tablets or capsule coating

- Lollipop or Candy Coating

- Cereal

- Pet Food Coating

- Snack food like popcorn, chips

- Chocolate-covered fruits

NOTE: Looking for flat lollipop making machine, Ball Lollipop Making Machine, Flat Lollipop Packing Machine, Coating Pan in Pune? Contact us today for more details and find the perfect crane for your needs!

Being is one of the foremost coating pan manufacturers in Pune, suppliers, and exporters in Pune. We at J.K. Engineering Works are committed to delivering the finest after-sales assistance worldwide whenever needed. Consequently, we guarantee a seamless operation at each stage of the candy production process.

FAQ:

In the food or pharmaceutical industry, some items like candies, tablets, pills, dry fruits, nuts, snacks, and many others can be coated with the help of a coating pan.

Yes, the latest models of coating pans are integrated with automated grades and processes, which are performed automatically. Due to this feature, production speed can be increased.

The high-quality Tablet Coating Pan is mostly used in the pharmaceutical industry to apply coatings on tablets, capsules, and pills.