Top Vacuum Batch Cooker Manufacturers in Pune | 2025

J.K. Engineering Works is one of the foremost vacuum batch cooker manufacturers in Pune, suppliers, exporters in Pune. We manufacture different kinds of cookers for cooling food products.

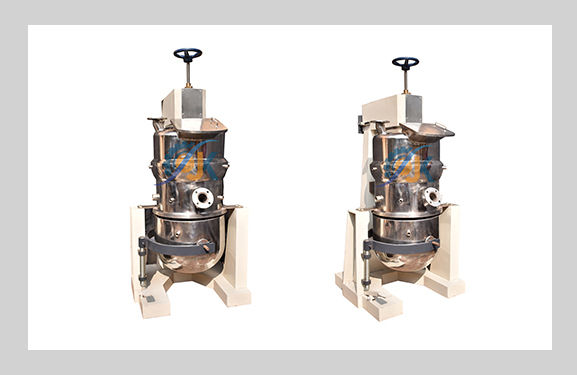

A vacuum batch cooker for candy & lollipop is a rapid cooling machine that uses a vacuum to cool the products. The moisture in these products evaporates, increasing their crust. Due to this machine, the efficiency of production has improved.

Types of Vacuum Batch Cooker:

Being a well-known vacuum batch cooker manufacturers in Pune, we design it in numerous types, which are given below:

- Multi-Stage Vacuum Batch Cooker:As the name suggests, cooling can occur in multiple stages and reduce extra temperature. This process decreases stress and prevents cracking on the products. It is best for baked food products. The high-quality MS batch cooker is used to prevent any kind of Bactria growth and maintain the hygiene.

- Continuous Vacuum Batch Cooker CVC: It is a vaccum candy cooker used in the manufacture of candy and confections to heat sugar mixtures under vacuum. It gives an accurate temperature regulation and moisture elimination. This method produces smooth and quality candy with a uniform texture and shorter cooking durations. The vacuum setting makes cooking at lower temperatures and helps to maintain flavors, hues, and nutritional value.

- Drying Vacuum Cooker (DVC): It is integrated with the drying system, which removes here and additional moisture from the products. It enables both cooling and moisture control and reduces humidity. This type of cooker is suitable for both small and large food applications. To harden or dry the candy, lab cooker for hard candy starch is used.

Technical Specifications of Vacuum Batch Cooker:

As a vacuum batch cooker manufacturers in Pune, suppliers, and exporters in Pune, here is the attached technical chart for more details.

| Specification | Details |

|---|---|

| Machine Type | Vacuum Batch Cooker, Vacuum Candy Batch Cooker |

| Stirrer Speed | 45 to 80 RPM |

| Material Used | Stainless Steel (SS304) |

| Brand | JK Engineering Works |

| Output Power | 1.5 HP |

| Phase | Three Phase |

| Input Voltage | 440V |

| Capacity | 60 kg/Batch |

| Dimension | L1200 x W1200 x H2000 mm |

| Automation Grade | Automatic |

| Frequency | 50 HZ |

| Features | Corrosion Resistant, Highly Durable, Easy to Clean |

Benefits of Vacuum Batch Cooker:

As leading vacuum batch cookers manufacturers in Pune, are highly acknowledged in the market for their given benefits:

- Faster Production: Vacuum batch cookers enable significantly faster product cooling than that of conventional air- or water-cooled products. More batches can be run in a short period, thus higher overall productivity.

- Uniformity in Cooling: In traditional cooling systems, temperature differences even throughout a batch can throw off that even cooling. All the products that are subjected to vacuum cooling come under the same conditions of vacuum; prompt exposure results in product temperature uniformity.

- Less Energy Consumption: As this candy vacuum batch cooker uses an evaporative cooling system, it requires less energy. Due to this feature, it makes a desirable choice for many customers. It also helps to reduce required costs and make it an economical solution.

Applications of Vacuum Batch Cookers:

As vacuum batch cooker suppliers in Pune, here are some applications of Industrial batch cooker mentioned.

- Food Industry: A vacuum batch cooker is mostly used in the food industry to cool cooked or baked products quickly. It decreases bacteria growth and improves the product’s hygiene and safety.

- Lollipop Production: On a large-scale lollipop production, our vacuum batch cooker is used to cool and harden a wide range of lollipops rapidly.

- Bakery and Products: To cool many bakery products like bread and toast, this cooker is used. It can evaporate this baked product’s moisture and get it cool within minutes.

Being a prominent vacuum batch cooker manufacturers in Pune, suppliers, and exporters in Pune, J.K. Engineering Works provides top-grade vacuum cooling solutions for various commercial and candy-making industries. Our customized cookers can meet multiple requirements of our client’s operation.

FAQ:

The system typically requires a power supply, vacuum line setup, and sometimes water access for cooling. Depending on the model, J.K. Engineering Works may provide specifications for installation and assist with setup and integration into existing production lines.

Depending on the applications, its operating temperature varies from -20°C to 50°C.